Plastic injection services

Plastic injection services are one of the important services of Navyan Plast Company. Plastic injection is done in all kinds of molds.

- What is plastic injection?

- Getting to know the plastic injection machine

- Types of plastic injection

- The stages of plastic production

- Types of plastic injection machines

- BT series plastic injection machine

- BS series plastic injection machine

- BU series plastic injection machine

- BH series plastic injection machine

- BM series plastic injection machine

- BE series plastic injection machine

- Chinese plastic injection machine

What is plastic injection?

One of the most convenient and most common and most important common methods for shaping polymers (resin) is using an injection machine. After the emergence and development of plastics, efforts were made to build devices that could easily shape plastic raw materials into the desired shape, which led to the invention of the injection machine.

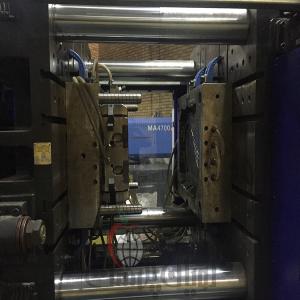

Getting to know the plastic injection machine

One of the most convenient and most common and most important common methods for shaping polymers (resin) is using a plastic injection machine. After the emergence and development of plastics, efforts were made to build devices that could easily shape plastic raw materials into the desired shape and led to the invention of the injection machine.

Types of plastic injection

Plastic is a product that is used for various purposes. Plastic may be hard or soft, transparent or opaque. It can look like wood or leather or silk. It can be used in making toys or heart valves. There are currently more than 10,000 different types of plastic.

The stages of plastic production

First, molds are prepared with great care and effort, then they are installed in manual clamps and a cylinder with a piston is installed on it, and the surrounding of the cylinder is heated with flames, and after the material is melted, it is pressed by the pressure of the top of the piston. The material inside the cylinder is injected into the mold, and after the material inside the mold cools down, we open the clamps and separate the pieces of the mold and remove the produced product from it, and all these steps were done by hand, until When today's modern injection machines were produced. The first injection machine that worked in a basic way was made in America in 1872, and the first advanced injection machine with a screw was registered in America in 1946 by James Watson.

1-Injection unit:

In this unit, melting, mixing and injection of materials take place.

First, the plastic material is poured into the hopper and enters the barrel from the hopper and is pushed forward by the rotation of the screw.

The cylinder shell is heated by the electric heaters (Heater) which are placed on the outer wall of the cylinder and turns into a liquid and reaches the front of the cylinder.

The auger rotates around to perform the material extraction (like a meat grinder) and also has a forward horizontal movement. At the same time, when the spiral moves forward, the materials already collected in the cylinder head and behind the valve are injected into the mold due to the pressure of the spiral.

After a specific period determined by the user of the device, the injection cylinder returns back by cutting off the pressure of the renewal spiral and the material taking action.

2- Dwelling:

The Dwelling phase includes a pause in the injection process so that both the melt inside the cavities are completely filled and the gases created are released from the built-in chambers.

3- Cooling:

At this stage, the melt is cooled until it becomes solid and can be removed from the mold. Otherwise, there is a high possibility of changing the shape of the product.

4- Mold Opening:

In this part, the Clamping section is opened so that the two halves of the molds are separated and ready to be launched.

5- Ejection:

A few rods together with a plate perform the process of removing the part from the mold. The runners and channels of the work piece that are unused and waste are separated from the piece and cleaned to prepare for melting again.

The price of a small plastic injection machine

Today, we see that small and light plastic parts have many uses. Therefore, small and large workshops in different cities produce them.

A small plastic injection machine is enough to produce light parts. But the phone calls that are made with us indicate that usually customers are looking to buy plastic injection machines larger than required. In a situation where the selling price of large plastic injection machines is higher than small machines.

The quality of the manufactured product, which is usually associated with high pressure from the plastic injection machine, leads the craftsmen to purchase plastic injection machines larger than what is needed for the production of parts. The following header is here to confirm this point.

Types of plastic injection machines

BT series plastic injection machine

In Polad's BT series plastic injection machine, smart pumps (variable flow rate) are used to control the oil output of the machine so that compared to fixed flow pumps that are constantly working and waste electrical energy, in addition to other side benefits, 30% to reduce electricity consumption and related costs by 70%. The pumps used in Polad BT series devices are made by Yuken company in Japan.

Polad's BT series injection machines as a fully equipped and economical device have been very popular among consumers. All these devices are equipped with KEBA control system made in Austria with full Persian menu. It also has a 3-plate clamping mechanism and is mass produced in various tonnages from 60 tons to 1800 tons. Dear customers, after consulting with the technical and engineering unit of Polad, and according to the dimensions of the mold, the type of material, the pressure and the weight of the injection they need, they can make the most suitable choice among the different tonnages of the devices.

BS series plastic injection machine

In Polad's BS series plastic injection machines, a servo pump motor is used for very precise control of oil pumping to the required parts of the injection machine, the main advantage of which is the reduction of electricity consumption and the resulting costs between 20% and 80%. compared to fixed flow and variable flow pumps. The pumps used in BS Polad series are manufactured by Voith or Eckerle, Germany.

Although these devices have a higher price than the BT series injection machines (devices equipped with a variable flow pump), they have a short return on investment due to greater savings in energy costs. All BS Polad series machines are equipped with the KEBA control system made in Austria with a completely Persian menu and also have a 3-plate clamp mechanism and are mass produced in various tonnages from 60 tons to 1800 tons. Dear customers, after consulting with the technical and engineering department of Polad Company, and according to the dimensions of the mold, the type of material, the pressure and weight of the injection they need, they can make the most suitable choice among the different tonnages of the devices.

BU series plastic injection machine

Polad's BU series plastic injection machines have a two-plate clamping mechanism, which are used to produce bulky parts (with great thickness and depth). These devices have many benefits compared to common three-plate devices, and due to the proper design of the clamping unit (use of 4 hydraulic jacks), it causes a homogeneous distribution of force behind the mold plates and, as a result, increases the life of the mold.

All Polad BU series injection machines are equipped with a servo pump motor made by Voith or Eckerle, Germany, as well as a 12-inch touch control system made by KEBA, Austria, with a completely Persian menu. These devices are produced in various tonnages from 500 tons to 6800 tons, which customers can choose the most suitable after consulting with the technical and engineering department of Polad company, and according to the dimensions of the mold, the type of material, the pressure and weight of the injection they need. Have devices of different tonnages.

BH series plastic injection machine

BH Polad series plastic injection machines have a two-plate clamping mechanism, which are used to produce bulky parts (with great thickness and depth). These devices have many benefits compared to the common three-plate devices, and also due to the proper design of the clamp unit (use of 4 hydraulic jacks), it causes a homogeneous distribution of force behind the mold plates and, as a result, increases the life of the mold.

BM series plastic injection machine

Polad's BM series plastic injection machines have a two-plate clamp mechanism that is used to produce bulky parts (with great thickness and depth). These devices have many benefits compared to common three-plate devices, and due to the proper design of the clamping unit (use of 4 hydraulic jacks), it causes a homogeneous distribution of force behind the mold plates and, as a result, increases the life of the mold.

BE series plastic injection machine

Polad's BE series plastic injection machines have a two-plate clamping mechanism, which are used to produce bulky parts (with great thickness and depth). These devices have many benefits compared to common three-plate devices, and due to the proper design of the clamping unit (use of 4 hydraulic jacks), it causes a homogeneous distribution of force behind the mold plates and, as a result, increases the life of the mold.

Chinese plastic injection machine

Regarding the plastic injection machine, the most important thing to be careful about is the plastic. What is plastic? It is a material that is used for different purposes and various products are made from it. Plastic can even look like leather, wood, and silk. It is used in making heart valves or making toys and thousands of other devices that are used daily.